Modern Clothing Manufacturing Bases

Nantong Sunrise Foreign Trade Co.,Ltd exclusively invested and holding invested 8 domestic and 1 Myanmar manufacturing bases. The group totally has 400 specialized and dedicated equipments like automatic cutting tables and automatic pocket-welt machines, and thousands of intelligent hanger system work stations. Annual production capacity is over 18 million pieces(sets).

Authorized by the trade headquarters, the Investment Management Department oversights and coordinates the production and operation of all the self-owned manufacturing bases. It develops and deploys high standards and quality control system to improve employee health and safety, drive for lean production and quality, and promote social responsibility and so on.

The group annually achieves the certification of SLCP, ISO9001 quality system, ISO14001 environment system standards, Work Safety Standardization, etcetera.

Specialized & Dedicated Equipments

Annual Production Capacity

Thousands

Intelligent Hanger System Work Stations

Manufacturing Bases Introduction

Nantong Sunrise Foreign Trade Co.,Ltd exclusively invested and holding invested 8 domestic and 1 Myanmar manufacturing bases. The group totally has 400 specialized and dedicated equipments like automatic cutting tables and automatic pocket-welt machines, and thousands of intelligent hanger system work stations. Annual production capacity is over 18 million pieces(sets).

Manufacturing Bases Management System

In the history of 24 years, the group has been adhering to the implementation of the whole process, closed-loop factory management, realized scientific and rigorous factory production.

Overall Management

Trade headquaters-- overall management Write and supervise the execution of "Sewing Factory Site Management"

Technical Management

Trade headquaters' technical department Nantong Sunrise Technical Management Center Technical department in each self-owned factory Manage Together

Quality Management

29 QC in trade headquaters' quality department Quality department in each self-owned factory Manage Together

Lead Time Management

Trade Headquaters' Production department Production department in each self-owned factory Manage Together

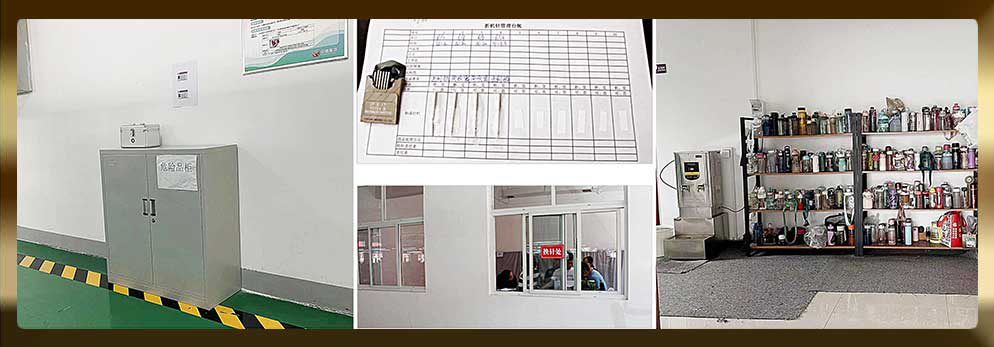

Fabric & Accessory Management

Fabric warehouse management Accessory warehouse management

Color Management

Strictly control color difference of fabric and accessory, and shrinkage

Health & Safety Management

Equipments cleaning & maintainance Adequate lighting on site Electric circuit control & No fire on site Regular safety inspection

1

贸易总部全局管理 制作并监督工厂执行《缝制工厂现场管理》

1

贸易总部全局管理 制作并监督工厂执行《缝制工厂现场管理》

1

贸易总部全局管理 制作并监督工厂执行《缝制工厂现场管理》

1

贸易总部全局管理 制作并监督工厂执行《缝制工厂现场管理》

Fabric Inspection & Loosening Management

10%-20% fabric random inspection Manage fabric loosening time and quantity according to fabric property

Warehouse Management

Stack by different styles Stack on trays or shelves Defective product isolated for 18 months

1

贸易总部全局管理 制作并监督工厂执行《缝制工厂现场管理》

1

贸易总部全局管理 制作并监督工厂执行《缝制工厂现场管理》

1

贸易总部全局管理 制作并监督工厂执行《缝制工厂现场管理》

1

贸易总部全局管理 制作并监督工厂执行《缝制工厂现场管理》

Hazardous Article & Personal Effects Management

Hazardous article management Broken needle & needle change management No entry of personal effects

Needle Inpection & Packing Management

Needle inspection order & judgment criteria Packing method & order Management

Inspection Management

1. Inspection in assembly line 2. Inspection before ironing 3. Inspection after ironing 4. Sunrise Garment Insepection-- final inspection

End Trimming & Ironing Management

End trimming gesture & order Ironing steam & folding & drying Management

Garment Wash Management

Test and confirm wash recipe & instruction Drying within 2 hours after wash

Sewing Works Management

Equipments cleaning & maintainance Sewing method & judgment criteria Storage of semi-finished products Management

Cut Pieces Management

Fabric spreading height & order Cut pieces inspection, numbering, stacking Management

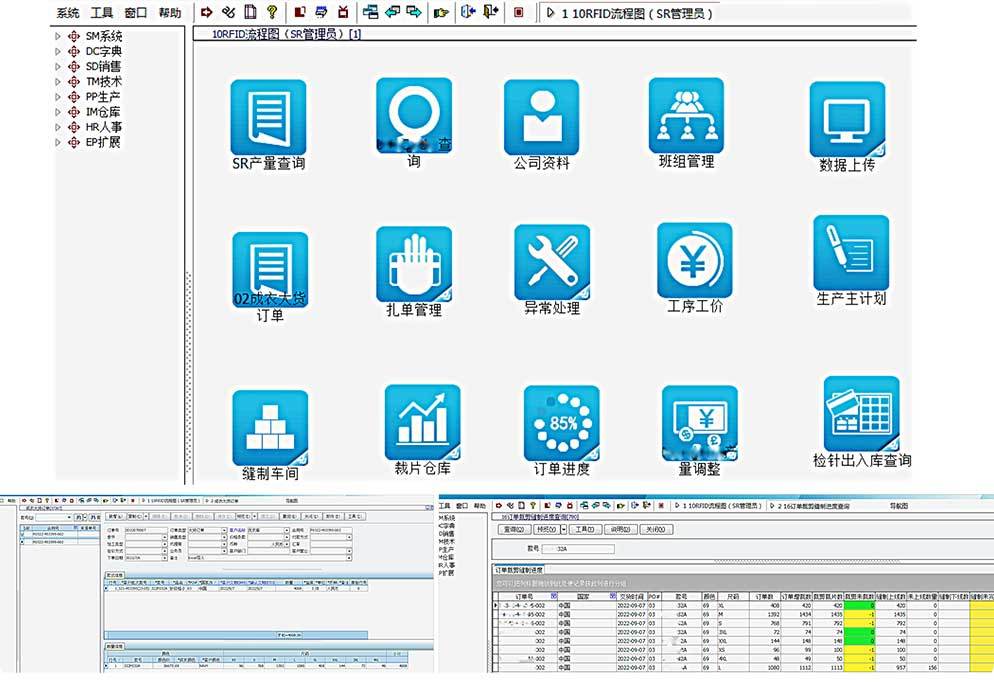

Automation & Intelligence & Informatization Introduction

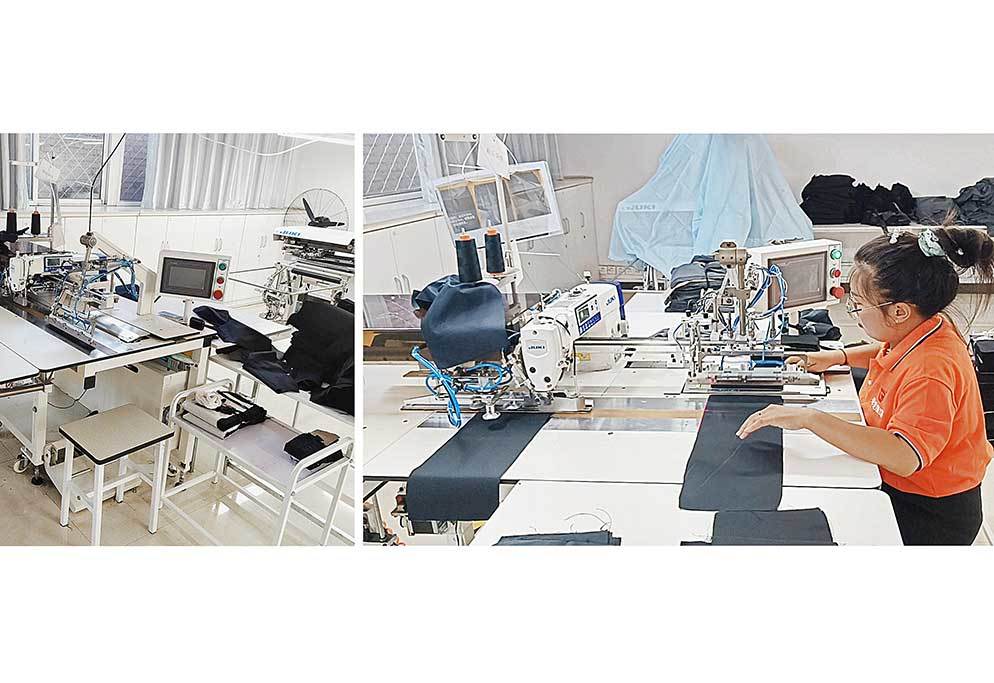

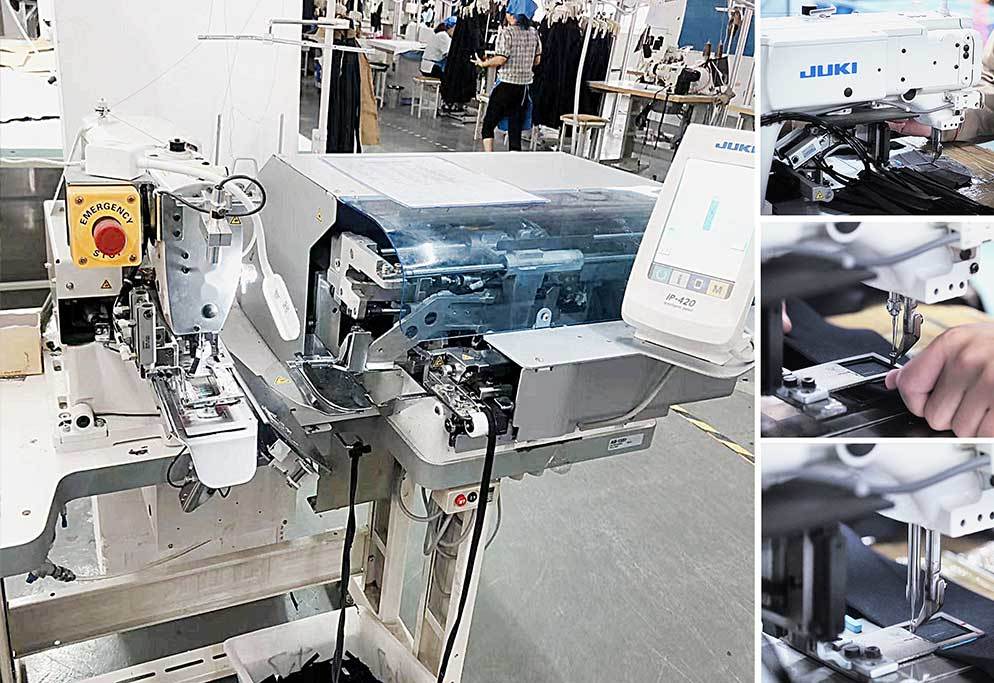

The group adheres to industrial upgradings, by replacing the traditional labor-intensive production methods with automation, intelligence, and informatization. The group totally has 400 specialized and dedicated equipments like automatic cutting tables and automatic pocket-welt machines, and thousands of intelligent hanger system work stations.

Intelligence & Informatization

3D Fashion Design Software

MES Intelligent Factory Management System

Customized ERP System

Intelligent Assembly Line System

Intelligent Hanger System

RFID Shipment System

Automation

Automatic Fabric Inspection Machine

Automatic Fabric Loosening Machine

Automatic Fabric Spreading Machine

Automatic Fabric Cutting Table

Automatic Pocket Facing Machine

Automatic Patch Pocket Machine

Automatic Pocket-welt Machine

Automatic Coin Pocket Machine

Automatic Ultra High Speed Overlock Machine

Automatic Elastic Cut & Joint Machine

Automatic Cord Tieing Machine

Automatic Belt Loop Machine

Automatic Pattern Seamer

Automatic Pattern Machine

Automatic 12-Neddle Sewing Machine

Automatic Double-Head Straight Button Hole Machine

Automatic Interlining Machine

ALL IN ONE Eco Dyeing & Wash & Drying Machine

Automatic End Trimming Machine

Automatic Elastic Staple Machine

Automatic Waist Tag Machine

Automatic Needle Inspection Machine

中文版

中文版 ENGLISH

ENGLISH 日本語

日本語